From First Contact to Finished Parts — We Make It Simple

Dedicated project managers guide you through every step. No language barriers. No surprises. Just precision manufacturing to take your project from prototype to mass production—without the supply chain headaches

24 hrs

Quote Response

1:1

Dedicated Manager

Fast

Production Time

Your Project Journey

Every successful project follows a clear path. Here's how we'll work together — from your first inquiry to parts in your hands.

Inquiry &

Consultation

Share your requirements and get expert guidance

Quotation &

DFM Review

Transparent pricing with design optimization

Sample

Development

Validate with production-grade prototypes

Production

Planning

Detailed timeline and milestone schedule

Manufacturing

& QC

Full visibility with quality checkpoints

Delivery &

Support

Secure packaging and ongoing partnership

What Happens at Each Step

Check the details of our transparent roadmap designed to ensure quality, reduce costs, and deliver on time.

Inquiry & Consultation

Day 1Share your project requirements with us. Our engineering team reviews your request and schedules a consultation to understand your goals.

- CAD files or drawings

- Quantity & timeline

- Application details

- 12-hour confirmation

- Feasibility review

- Dedicated contact

Quotation & DFM Review

1-2 DaysReceive detailed quotation with transparent pricing — no hidden fees. Our engineers provide DFM feedback to optimize for cost and quality.

- Spec confirmation

- Clarifying answers

- Material preferences

- Itemized pricing

- DFM analysis

- Timeline estimate

Sample Development

7-15 DaysValidate your design with physical samples using production-grade tooling and materials. What you approve is what you'll receive at scale.

- Approval to proceed

- Sample quantity

- Design refinements

- Physical samples

- Inspection report

- Material certs

Production Planning

3-5 DaysOnce samples are approved, we lock in your production schedule. Our team coordinates material sourcing, tooling, and scheduling.

- Sample approval

- Order quantity

- Payment

- Delivery needs

- Production timeline

- Milestone schedule

- QC plan

Manufacturing & QC

2-6 WeeksYour parts enter production with rigorous QC at every stage. You'll receive regular updates with photos and progress reports.

- Nothing — we handle it

- Optional: visit scheduling

- Weekly updates

- Inspection reports

- Part photos

Delivery & Support

On ScheduleParts are professionally packaged and shipped via your preferred carrier. Our relationship doesn't end at delivery — we're here for ongoing support.

- Shipping preference

- Delivery address

- Import docs needed

- Secure packaging

- Full documentation

- Tracking info

Typical Timelines

Simple Projects

3-4 weeks

Standard Projects

5-8 weeks

Complex Projects

8-12 weeks

What We Need From You

You don't need perfect drawings or finalized designs to begin. Here are three ways to start your project with us.

You Have Drawings

If you have CAD files or technical drawings, you're ready for a detailed quote. Upload your files and we'll review them within 24 hours.

- 3D: STEP, IGES, STP, SLDPRT

- 2D: DWG, DXF, PDF

- Include tolerances & material specs

You Have a Sample

Have an existing part you want to replicate or improve? Send us a sample and we'll reverse-engineer it with precision measurements.

- Competitor parts to match

- Worn parts to reproduce

- Legacy parts with no drawings

You Have an Idea

Even rough sketches or verbal descriptions are enough to start. Our engineering team can help develop your concept into manufacturable designs.

- Hand sketches or photos

- Reference products or images

- Performance requirements

Not sure which option fits your situation?

No problem. Contact us with whatever you have and we'll guide you from there. Every project is different, and we've helped hundreds of customers go from concept to finished parts.

- Our Commitment to You

What You Can Expect From Us

Working with an overseas manufacturer shouldn’t mean uncertainty. Here’s what we promise to every customer:

24-Hour Response Guarantee

Every inquiry receives a response within one business day. Questions answered. Quotes initiated. No waiting, no wondering if your email was received.

Transparent, Itemized Pricing

Our quotes break down every cost component: Parts, tooling, Surface finishing, and shipping. You'll understand exactly what you're paying for — no hidden fees, no surprises at invoice time.

Quality Guarantee

Every part is inspected before shipping. If anything doesn't meet the agreed specifications, we make it right — replacement parts at no charge, expedited shipping on us.

On-Time Delivery

When we commit to a delivery date, we mean it. Our production planning accounts for real-world variables, and we communicate proactively if anything changes.

Professional Communication

Our sales team and engineers all have more than 3 years of experience in this area, and they can understand what you're saying.

Ready to experience the difference?

Project Types We Handle

Whether you need one prototype or one million production parts, we have the capabilities and flexibility to deliver.

|

|

|

|

|

|---|---|---|---|

|

Timeline

|

7-15 Days | 2-4 Weeks | 4-8 Weeks |

|

Best For

|

R&D Teams, Designers | Startups, Market Testing | OEMs, Established Products |

|

Tooling

|

Soft / Rapid Tooling | Economical Tooling | Optimized Production Tooling |

|

DFM Feedback

|

|||

|

Quality Inspection

|

|||

|

JIT / Kanban Delivery

|

— | Available | Optimized |

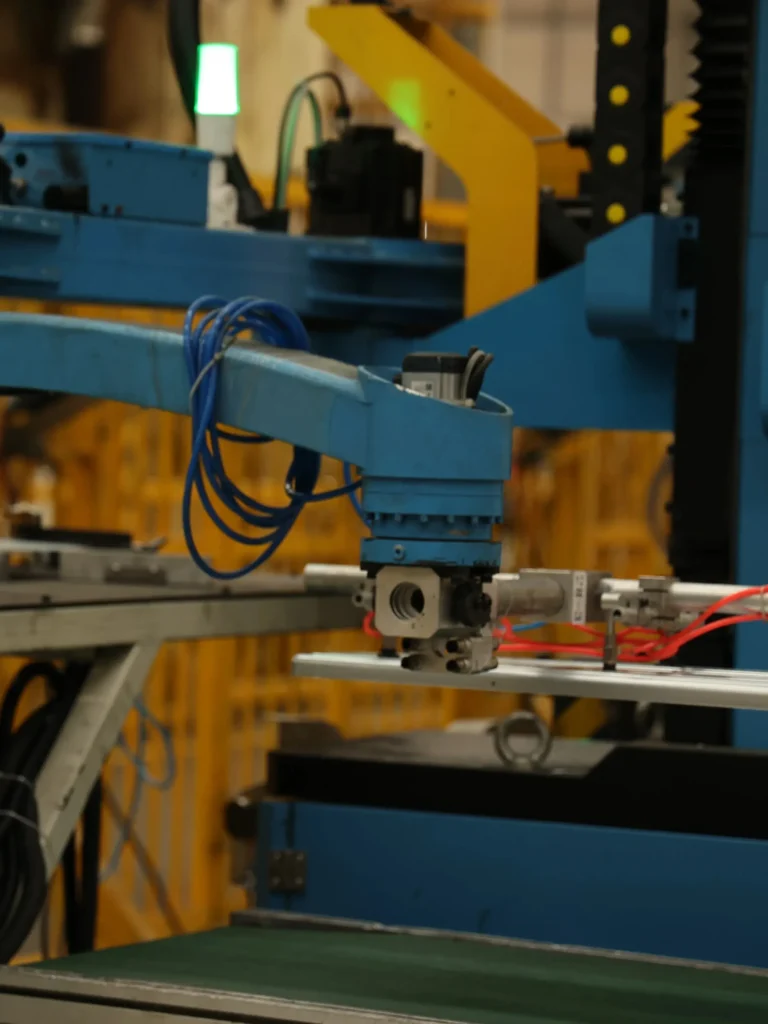

Why Choose ZAK

Four decades of manufacturing excellence, trusted by global OEMs.

40+ Years of Expertise

Experienced engineers and skilled workers with decades of hands-on manufacturing knowledge.

One-Stop Manufacturing

Sheet metal, stamping, surface finishing, and assembly — all under one roof.

Trusted by Global OEMs

Manufacturing for Honda, Midea, Carrier, Panasonic and other industry leaders.

Your IP, Your Tooling

NDA signed upfront. Strict access controls. All tooling remains your property.

Useful Resources for You

Explore our guides and tools to prepare your project for manufacturing success.

Sheet Metal Design Guide

DFM tips, bend radius, tolerances for better manufacturability

Surface Finishing Options

Powder coating, plating, anodizing – compare finishes

Material Selection Guide

Steel, aluminum, stainless – properties & applications

Request for Quote Form

Submit your project details and files for a comprehensive quote within 24 hours.

Quality & Certifications

Our ISO, IATF standards and inspection process

Packaging & Shipping

How we protect and deliver your parts globally

Q: What information do I need to get a quote?

A: At minimum, we need to understand what you want to make: drawings, a sample, or even a concept description. The more detail you provide — materials, quantities, tolerances, finishes — the more accurate your quote will be. But don’t wait until everything is perfect. We can help fill in the gaps.

Q: How quickly can I expect a quote?

A: Standard quotes are delivered within 24 hours of receiving your files. Complex projects with multiple parts or special requirements may take 2-3 days. Rush quotes are available if you need faster turnaround — just let us know.

Q: Do you offer design assistance?

A: Yes. Our engineering team can help develop concepts into production-ready designs, optimize existing drawings for manufacturability, or reverse-engineer samples into CAD files. Design support is often included in the quotation process at no extra charge for production projects.

Q: What file formats do you accept?

A: For 3D models: STEP, IGES, STP, X_T, Parasolid, SLDPRT, and most major CAD formats. For 2D drawings: DWG, DXF, and PDF. If you have a format not listed, send it anyway — we can usually work with it.

Q: Can I visit the factory?

A: Yes, and we encourage it. Factory visits can be arranged for qualified customers. We’ll coordinate your visit, arrange transportation from Guangzhou airport, and provide a comprehensive facility tour. Many customers combine factory visits with a quality audit before starting production.

Q: How do you protect my intellectual property?

A: We take IP protection seriously. We sign Non-Disclosure Agreements (NDAs) upon request before reviewing any project details. Your designs and tooling are your property. We never share customer designs, use them for other customers, or sell parts to third parties without explicit authorization.

Q: What quality certifications do you hold?

A: We maintain ISO 9001:2015 certification for our quality management system and IATF 16949 certification for automotive quality standards. We also comply with RoHS environmental requirements and can provide material certifications, inspection reports, and full traceability documentation.

Q: What happens if parts don't meet specifications?

A: If any parts don’t conform to the agreed specifications, we make it right at no cost to you. Depending on the situation, this may mean producing replacement parts, issuing a credit, or expediting a new shipment. We aim to resolve quality issues within 48 hours of notification.

Q: Are tooling costs separate from part costs?

A: Yes, tooling is quoted separately and remains your property. For simple sheet metal parts, tooling may be minimal or included. For stamping dies, molds, or complex fixtures, tooling is a one-time investment that we amortize or quote separately. All tooling costs are clearly itemized in your quote.

Q: Do you handle international shipping?

A: Yes. We ship globally via air freight (DHL, FedEx, UPS) or sea freight depending on your timeline and cost preferences. We prepare all export documentation, commercial invoices, packing lists, and can provide customs paperwork for most destinations.

Common Questions

Find answers to the questions we hear most often. Don’t see yours? Contact us directly.

Start Your Project

Whether you have detailed CAD files or just a napkin sketch, we’re ready to help bring your project to life. Start with a quote request, or schedule a call to discuss your requirements.