Foam Sealing & FIPG Gasket Dispensing

CNC-dispensed polyurethane foam gaskets applied directly to your sheet metal parts — IP65/IP66 rated, seamless, and waste-free.

At ZAK, our foam sealing service is a core part of our integrated sheet metal fabrication workflow. We eliminate the complexity and lead time of managing separate gasket suppliers and manual assembly. Your parts arrive with a perfectly applied, high-performance foam gasket already cured in place, ready for immediate integration into your final product.

What is Foam Sealing (FIPG)?

Formed-In-Place-Foam-Gasket (FIPG) technology is an advanced sealing solution where a two-component liquid polyurethane (PU) material is precisely mixed and dispensed by a CNC robot directly onto the surface of a component. The liquid bead reacts and cures at room temperature, expanding to form a soft, resilient, closed-cell foam gasket that is permanently bonded to the part.

This automated process creates a seamless seal that perfectly follows the most complex part geometries, providing superior protection against dust and water ingress.

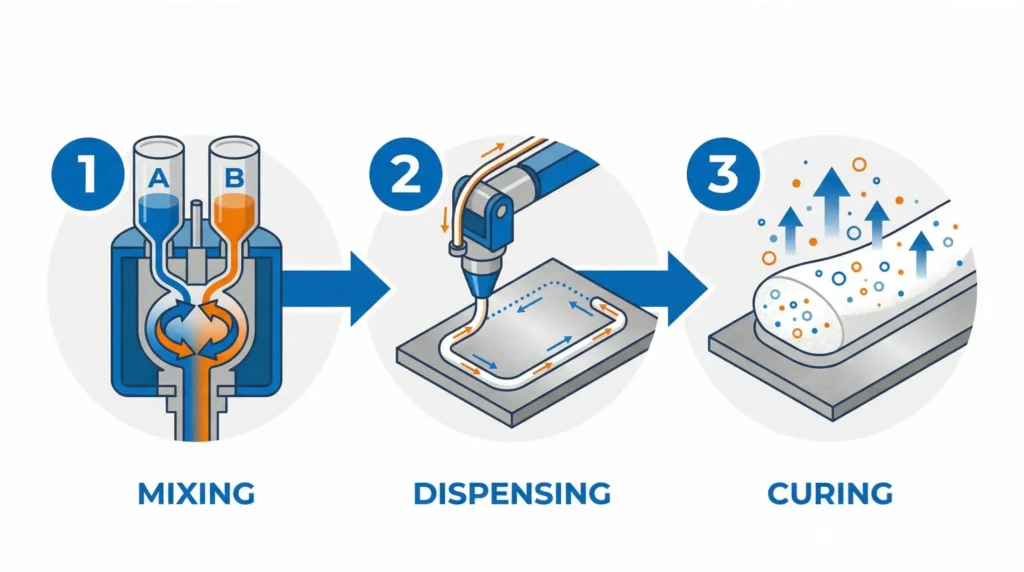

How It Works: A Three-Step Process

1

Mixing

The two-component PU material (a polyol and an isocyanate hardener) is precisely metered and dynamically mixed in the dispensing head to initiate the chemical reaction.

2

Dispensing

A CNC-controlled robot traces the programmed gasket path on the component, applying a continuous liquid bead with exceptional accuracy.

3

Curing

The material foams and cures at ambient temperature, expanding by over three times its liquid volume to create a permanent, compressible, and high-performance seal.

Key Properties of Cured PU Foam Gaskets

- Closed-Cell Structure: Prevents water absorption and ensures a reliable, long-lasting seal.

- Excellent Compression Recovery: Returns to original shape after repeated compression cycles.

- Superior Adhesion: Bonds strongly to steel, stainless steel, aluminum, and powder-coated surfaces

- Durability: Resistant to UV, ozone, and temperature range of -40°C to +90°C.

FIPG vs. Traditional Gaskets: Which is Right for Your Application?

Engineers and procurement managers often weigh the benefits of FIPG against traditional sealing methods like die-cut gaskets and adhesive foam tape. While each has its place, FIPG offers significant advantages for production-scale manufacturing of enclosures and complex parts.

The comparison below highlights the key differences that make FIPG the preferred choice for modern manufacturing.

| FACTOR | FIPG (FOAM SEALING) | DIE-CUT GASKETS | ADHESIVE FOAM TAPE |

|---|---|---|---|

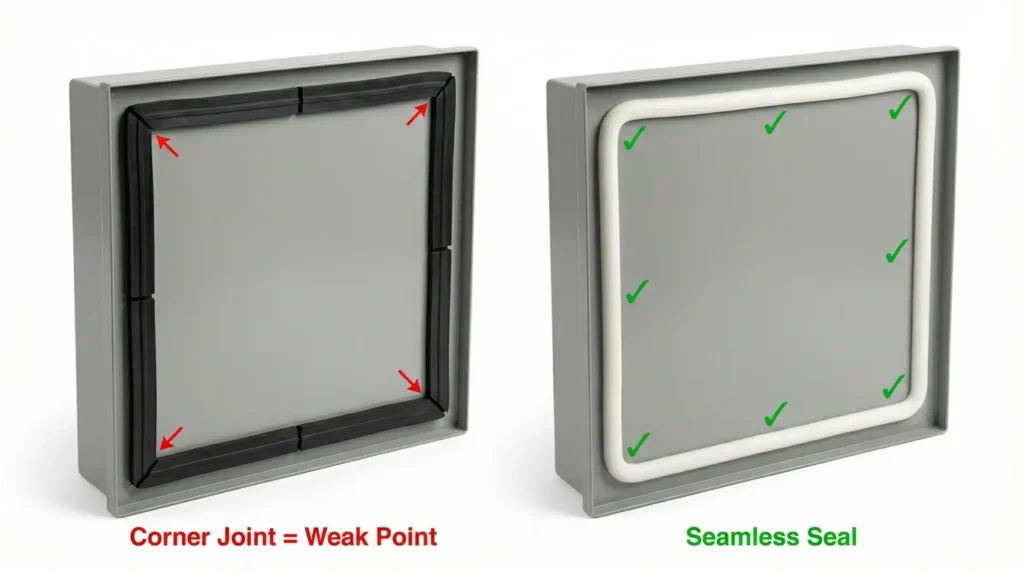

| Seal Continuity | Seamless, continuous bead with no joints | Joints at corners are inherent weak points | Manual joints create potential leak paths |

| Precision | CNC-controlled path (±0.5mm) | Dependent on die tolerance | Reliant on manual skill |

| Material Waste | Near-zero waste (additive process) | Significant material scrap | End-of-roll waste |

| Assembly Labor | Zero — applied during fabrication | Requires manual installation | Time-consuming manual application |

| Complex Geometries | Handles 3D contours and curves | Limited by die-cutting capabilities | Very difficult for complex paths |

| Tooling Cost | No tooling required | Custom die for every shape | None |

| IP Rating | Consistently achieves IP65/IP66 | Variable; depends on installation | Lower reliability |

| Best For | Production volumes, complex enclosures | Simple, flat surfaces | Prototypes, field repairs |

Our Foam Sealing Capabilities

ZAKFAB has invested in state-of-the-art CNC foam dispensing technology to provide our clients with reliable, high-quality, and cost-effective integrated sealing solutions. Our equipment and materials are selected to meet the demanding requirements of modern industrial, electrical, and automotive applications.

Equipment & Technology

- CNC Foam Dispensing System: Multi-axis FIPFG robotic system for precise application

- Automated Mixing & Dosing Unit: Perfect A:B component ratio control

- Programmable Bead Width: 3mm – 15mm

- Programmable Bead Height: 2mm – 12mm (after curing)

Materials

We offer a range of polyurethane and silicone-based foam systems to match your specific performance and environmental requirements.

- Polyurethane (PU) Foam: Industry standard for electrical enclosures and HVAC panels. Temperature range: -40°C to +90°C.

- Silicone Foam: For high-temperature applications (up to +180°C) and enhanced chemical resistance.

Technical Specifications

| SPECIFICATION | VALUE |

|---|---|

| Maximum Part Size | 1500mm x 800mm |

| Dispensing Accuracy | ±0.5mm |

| Gasket Profile | Round, Triangular, or Flat-Top |

| Cure Time | Tack-free in 5–30 minutes |

| Supported Substrates | Steel, Stainless Steel, Aluminum, Galvanized, Powder-Coated |

Our Foam Sealing Process: Transparency and Control

We believe in process transparency. Our CNC foam sealing process is a tightly controlled, six-step workflow that guarantees quality and repeatability from the first part to the ten-thousandth.

| STEP | NAME | DESCRIPTION |

|---|---|---|

| 1 | Part Preparation | Fabricated parts are thoroughly cleaned and inspected. A pristine surface is critical for maximum gasket adhesion. |

| 2 | Program Setup | The gasket path is programmed into the CNC system directly from your CAD file. |

| 3 | Material Mixing | Two-component PU or silicone is precisely metered and mixed in the dispensing head. |

| 4 | CNC Dispensing | The robotic arm traces the programmed path, applying a continuous, seamless gasket bead. |

| 5 | Curing & Expansion | The material reacts at room temperature, foaming to create the final gasket profile. |

| 6 | Inspection & QC | Every sealed part undergoes final quality check for continuity and dimensional accuracy. |

Understanding IP & NEMA Ratings for Sealed Enclosures

IP (Ingress Protection) and NEMA (National Electrical Manufacturers Association) ratings are crucial standards that define the level of protection an enclosure provides against environmental factors like dust and water. Our foam sealing service is specifically designed to help your products achieve reliable IP65 and IP66 ratings.

IP Rating Reference Guide

| RATING | DUST PROTECTION | WATER PROTECTION | TYPICAL APPLICATION |

|---|---|---|---|

| IP65 | Dust-Tight | Protected against water jets (6.3mm nozzle) | Outdoor electrical boxes, rain exposure |

| IP66 | Dust-Tight | Protected against powerful water jets (12.5mm nozzle) | Marine applications, wash-down environments |

| IP67 | Dust-Tight | Protected against temporary immersion (up to 1m) | Equipment that may be temporarily submerged |

NEMA to IP Cross-Reference

| NEMA TYPE | APPROXIMATE IP EQUIVALENT | ENVIRONMENT |

|---|---|---|

| NEMA 3R | IP14 | Outdoor, rain protection |

| NEMA 4 | IP66 | Outdoor/indoor, windblown dust, water jets |

| NEMA 4X | IP66 | Same as NEMA 4 with corrosion resistance |

| NEMA 12 | IP55 | Indoor, dust and drip protection |

Industries & Applications

From rugged outdoor equipment to sensitive electronics, our integrated foam sealing solutions provide reliable environmental protection across a wide range of industries. We partner with leading OEMs to deliver sealed components that perform in the most demanding conditions.

HVAC & Climate Control

- Outdoor unit panels and cladding

- Air handling unit access doors

- Filter frame sealing

Electrical & Power Distribution

- Electrical enclosure doors and covers

- Control cabinet sealing

- Junction box covers

Automotive

- EV battery enclosure sealing

- ECU housing seals

- Lighting housing gaskets

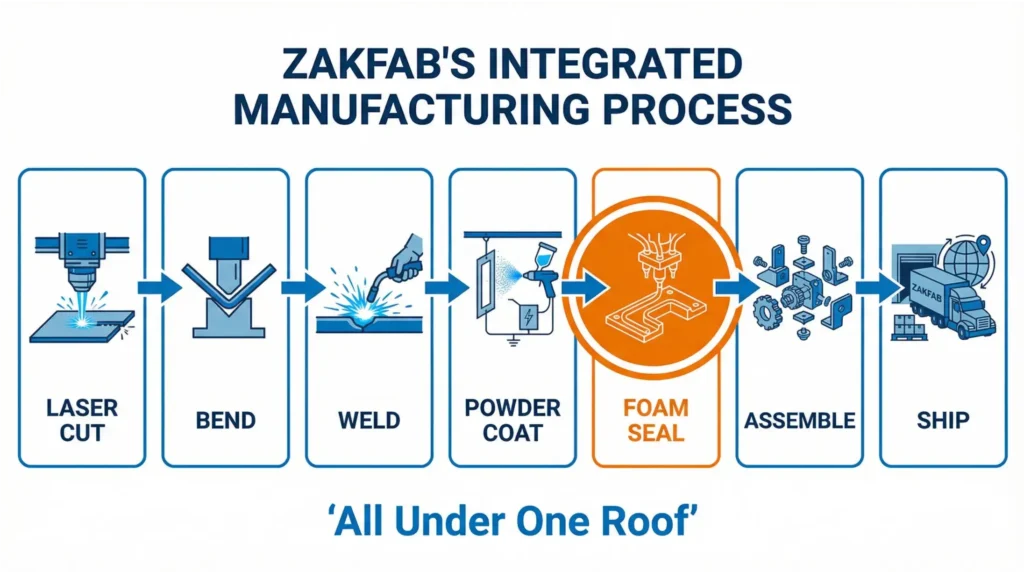

The Integrated Advantage: One Partner, from Fabrication to Sealing

Traditionally, sourcing sealed sheet metal parts meant managing a complex supply chain: a fabricator, a separate gasket manufacturer, and an assembler. Each handoff adds cost, lead time, and risk.

ZAK eliminates this complexity. We offer a fully integrated workflow, from raw material to the final sealed and assembled component, all under one roof.

Quality Assurance for Mission-Critical Sealing

For IP-rated components, quality is non-negotiable. Our quality management system, certified to ISO 9001 and IATF 16949, includes specific checks to ensure the performance of every foam gasket we produce.

- Gasket Bead Measurement: Go/no-go gauging for bead width and height

- Adhesion Testing: Cross-hatch adhesion tests per batch

- Visual Inspection: 100% check for bead continuity

- IP Rating Verification: Water spray and dust chamber testing available

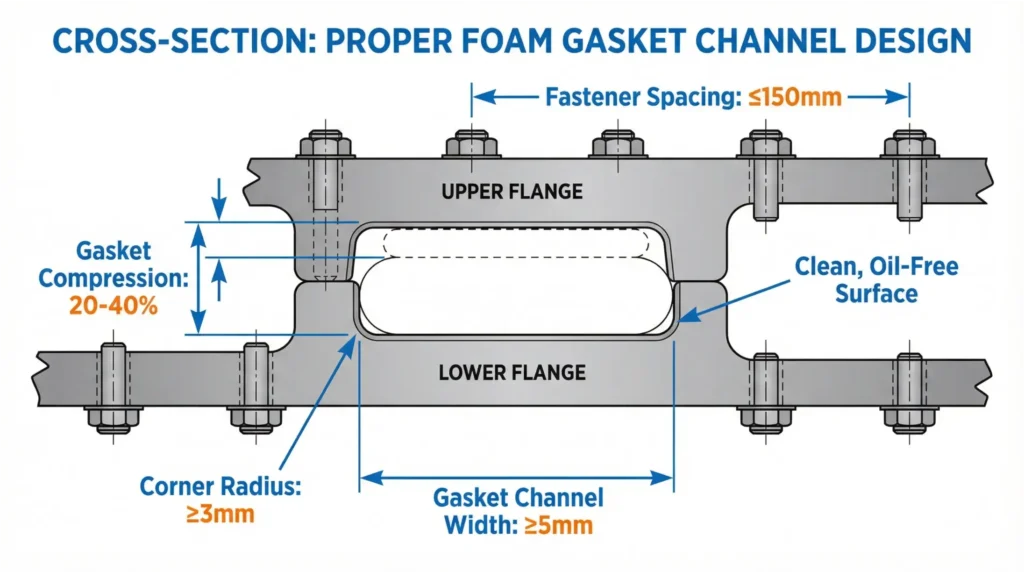

DFM Guidelines for Foam-Sealed Parts

Partner with us in the design phase to optimize your parts for foam sealing. Following these Design for Manufacturability (DFM) guidelines will ensure a robust, reliable, and cost-effective seal.

| GUIDELINE | RECOMMENDATION | WHY IT MATTERS |

|---|---|---|

| Gasket Channel | Provide a flat surface ⩾5mm wide | Ensures proper bead adhesion and compression |

| Corner Radius | Minimum inside radius ⩾3mm | CNC dispensing head needs room to turn |

| Surface Finish | Clean, dry, oil-free. Powder coating OK | Contamination causes adhesion failure |

| Compression Design | Design for 20–40% gasket compression | Under-compression = leaks; over-compression = failure |

| Fastener Spacing | Maximum 150mm between fasteners | Prevents bowing and uneven compression |

Need Help? Upload your drawing for a free DFM review →

Frequently Asked Questions

What IP rating can foam sealing achieve?

Our PU foam sealing reliably achieves IP65 and IP66 ratings with proper enclosure design. For IP67 (temporary immersion), we typically recommend solid rubber gaskets for maximum reliability.

Can you apply foam sealing to powder-coated parts?

Yes, absolutely. Powder-coated surfaces provide an excellent, clean substrate for gasket adhesion. We apply the gasket after powder coating as part of our integrated workflow.

What is the minimum order quantity?

There is no MOQ. Because CNC dispensing is a toolless process, we can cost-effectively support everything from single-unit prototypes to high-volume production runs.

How long does the foam gasket last?

Under normal operating conditions, our PU foam gaskets maintain their sealing properties for over 10 years. They are formulated to resist UV, ozone, and temperature cycling.

Do you offer foam sealing as a standalone service?

While our core strength is integrated manufacturing, we can discuss foam-sealing-only projects. However, we achieve the best quality and cost-effectiveness when we control the entire process from fabrication to sealing. Contact us to discuss your specific needs.

Related Services

Ready to Get Started?

Whether you have detailed CAD files or just a napkin sketch, we’re ready to help bring your project to life. Start with a quote request, or schedule a call to discuss your requirements.