66,000 m² of Integrated Metal Manufacturing

Located in China’s premier manufacturing hub, our facility houses everything from sheet metal fabrication and precision stamping to surface finishing and assembly, all under one roof.

Take a Virtual Tour

Can’t visit in person? Explore our manufacturing facility from anywhere in the world with our guided video tour.

Explore Our Manufacturing Departments

Each department is equipped with state-of-the-art machinery and staffed by experienced technicians to deliver precision results.

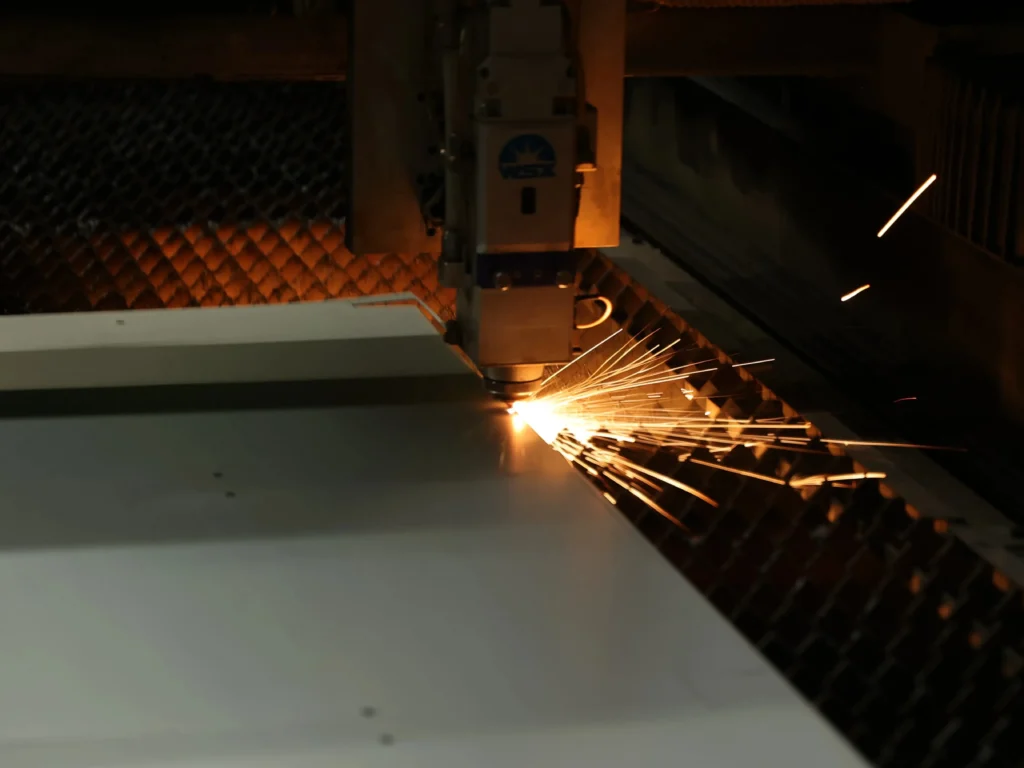

Sheet Metal Fabrication Center

Our sheet metal department features advanced laser cutting systems, CNC bending machines, and automated production lines for high-precision fabrication of enclosures, panels, and structural components.

Equipment & Capabilities

- Laser Cutting

- CNC Press Brake

- CNC Punch

- Sheet Metal Bending

- Shearing & Forming

- Prototyping

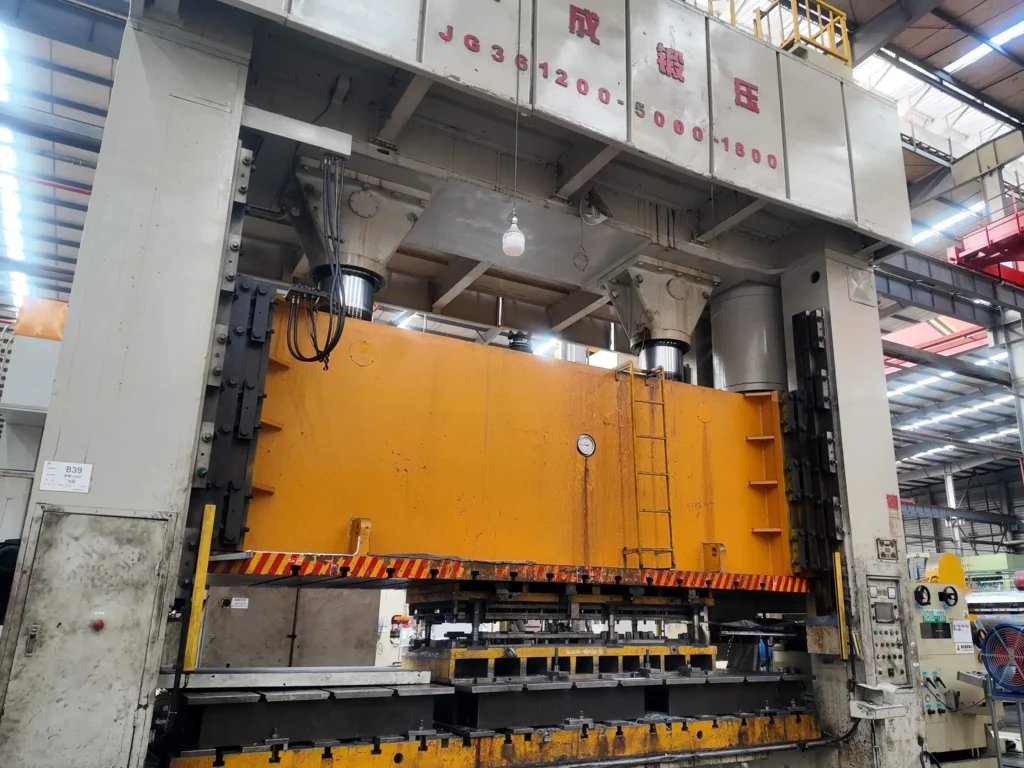

Stamping Department

Housing 100+ stamping presses ranging from 110T to 1200T, our stamping department handles everything from small precision components to large structural stampings with progressive and transfer die capabilities.

Equipment & Capabilities

- Progressive Die Stamping

- Deep Drawing

- Compound Dies

- Automated Production Line

- High-Speed Precision

- Multi-Station Transfer

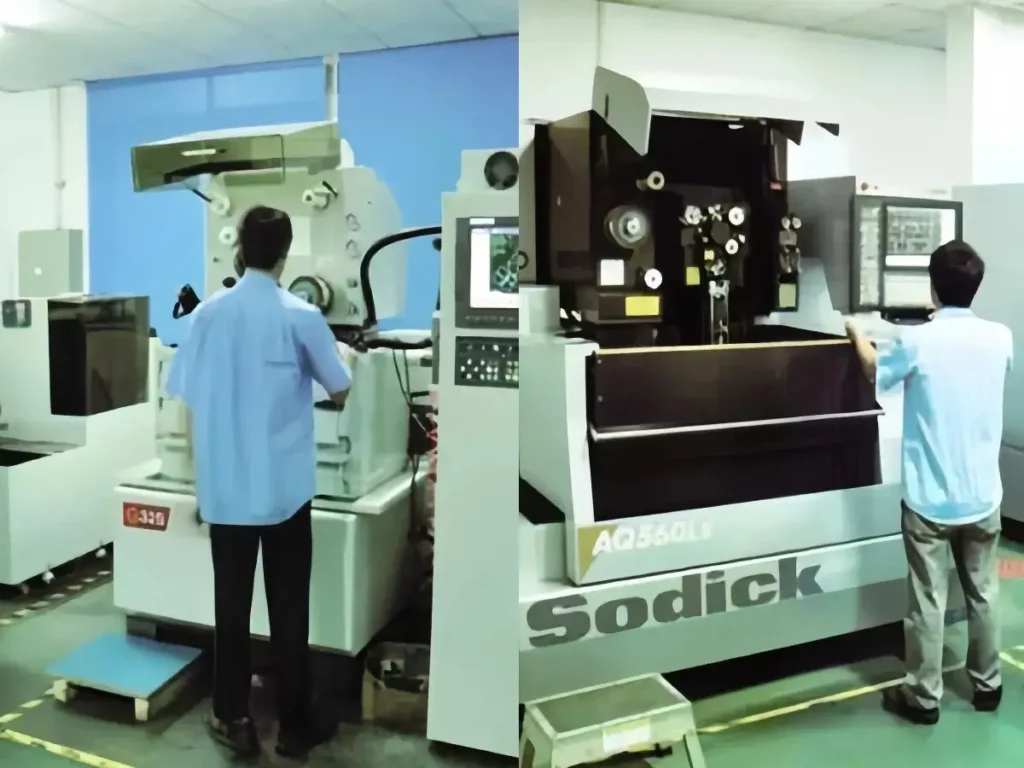

In-House Tool & Die Workshop

Our dedicated tooling department designs and manufactures custom dies and molds in-house, enabling faster turnaround, better quality control, and immediate tooling maintenance when needed.

Equipment & Capabilities

- CNC Machining Centers

- Surface Grinders

- Tool Repair & Maintenance

- Wire EDM Machines

- CAD/CAM Design

- Die Tryout Presses

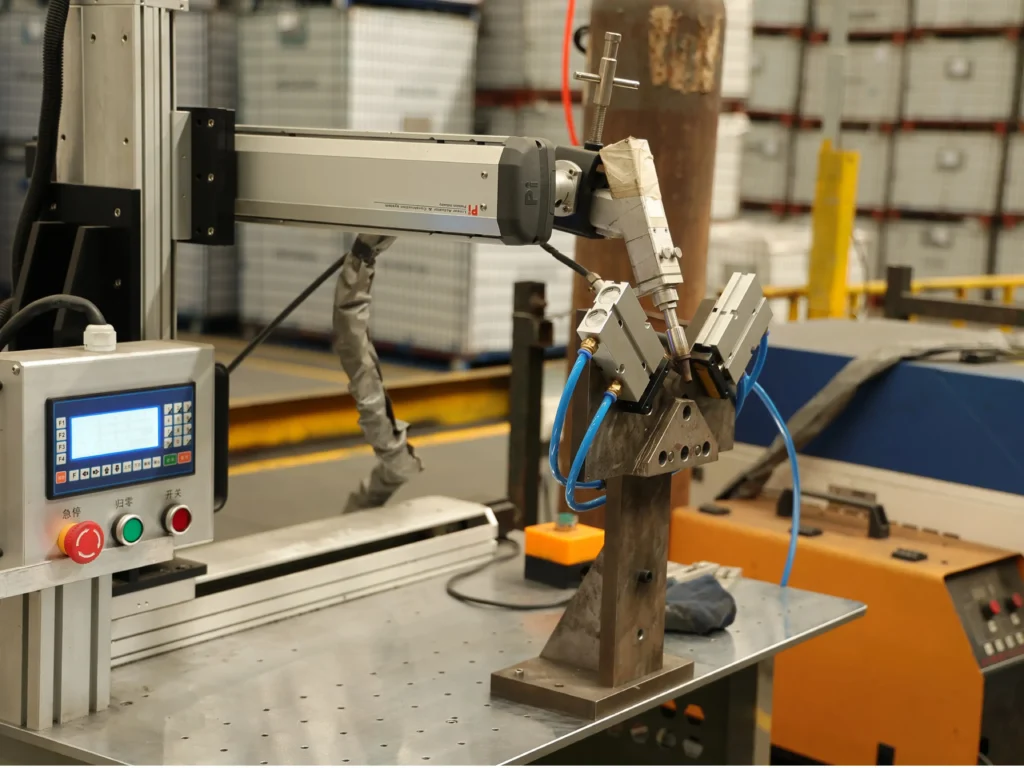

Welding & Assembly Center

Combining robotic precision with skilled manual craftsmanship, our welding department handles MIG, TIG, and spot welding for complete product assembly and integration.

Equipment & Capabilities

- Robotic Welding Cells

- Spot Welding

- Hardware Installation

- MIG/TIG Welding

- Stud Welding

- Final Assembly

Surface Treatment & Finishing

Our automated finishing lines provide powder coating, anodizing, plating, and other surface treatments to protect and enhance your products’ appearance and durability.

Equipment & Capabilities

- Powder Coating Line

- Zinc Plating

- Polishing

- Anodizing

- Brushing

- Screen Printing

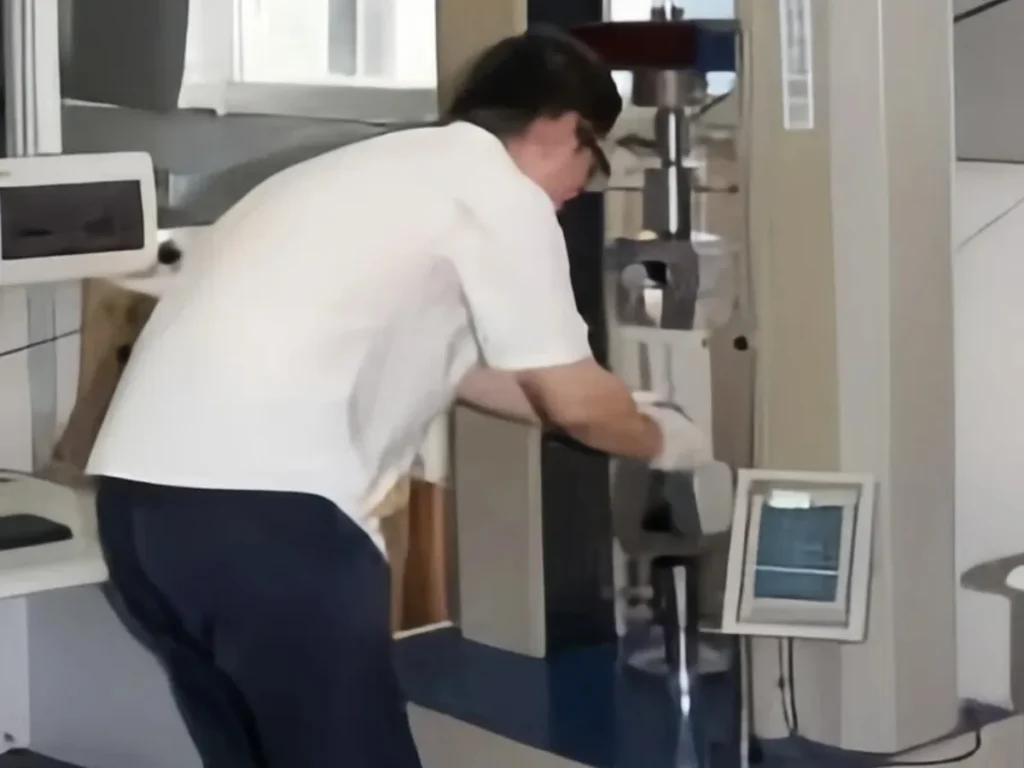

Quality Assurance Laboratory

Our dedicated QC lab is equipped with advanced measurement and testing equipment to ensure every part meets specifications before shipment. Full traceability and documentation provided.

Equipment & Capabilities

- CMM Machine

- Salt Spray Chamber

- Spectrometer

- 2D Measurement

- Hardness Testers

- Coating Thickness Gauge

Equipment Inventory

Over 200 advanced machines across stamping, fabrication, welding, and finishing operations.

Featured Capability

Large-Tonnage Stamping Presses

Our heavy-tonnage presses (800T-1200T) enable production of large structural components up to 2000×1200mm, serving automotive and commercial HVAC industries.

1200T

Max Tonnage

5m

Max Bed Size

76

Heavy Presses

1200T Hydraulic Press

Rongcheng, JG36-1200, 1 Unit, For Large structural parts in a single forming operation

Bed Size

5000×1800mm

Max Part

2000×1200mm

800T Hydraulic Press

Xieduan / Jinan, YzS-800T, 3 Units, For complex deep-draw forming

Bed Size

3000×2000mm

Application

Deep Draw

400T-600T Medium Presses

Jinan / Korea, Multiple Models, 6 Units, For medium-sized components

Bed Size

4000×1600mm

Type

Progressive Die

200T-300T Precision Presses

SIMPAC / Jinan, 15 Units, High-speed production for mid-size precision parts

Quantity

30 sets

Application

Medium Parts

110T-160T High-Speed Presses

Fast cycle times for precision small parts

Quantity

41 sets

Application

Precision Parts

60T-80T Light Presses

Small to Medium Parts at high volumes

Quantity

20 sets

Brand

Komatsu 200T

Robot Welding Cells

Automated precision for consistent, repeatable welds

Type

6-Axis Robot

Application

Auto Welding

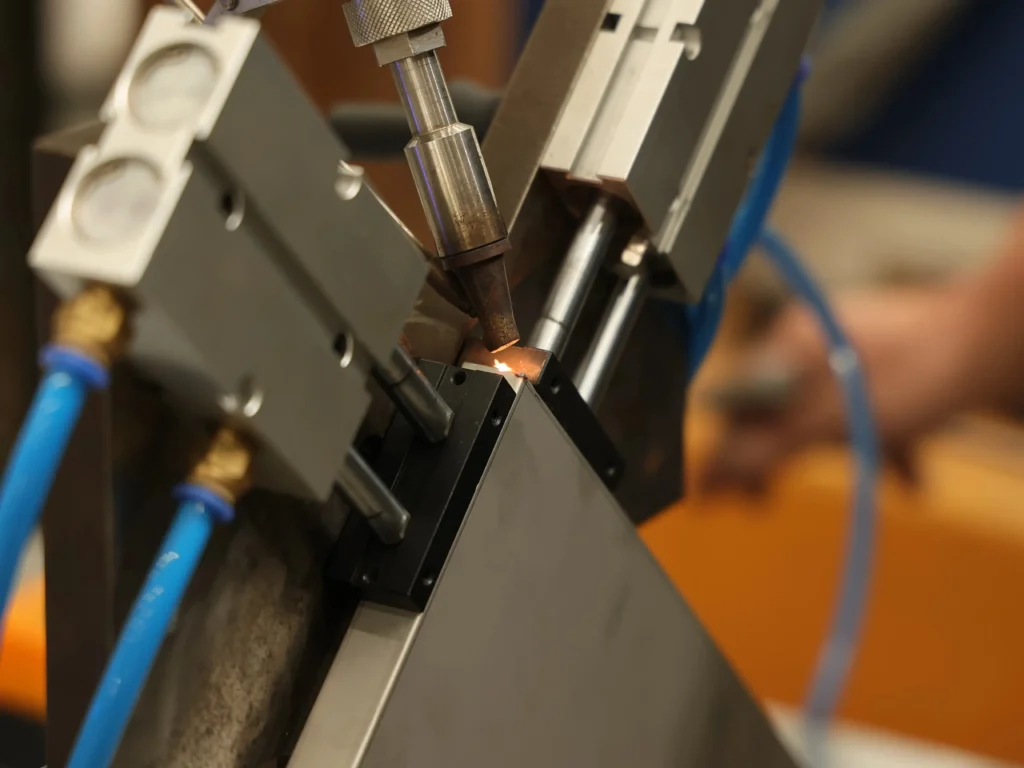

Laser Welding

Minimal heat distortion for precision assemblies parts

Type

Fiber Laser

BENEFIT

Clean seams

Resistance Spot Welding

Fast cycle times for high-volume sheet metal assembly

CAPACITY

15×DN-40 1×HBIII

APPLICATION

Panel assembly, enclosures

MF Welders

Superior weld quality meeting automotive standards

MODEL

CDI 2302

Application

Automotive

Laser Cutter

HL-CFR3015E, Fast, precise cutting with minimal material waste

Power

3000W

Bed Size

1500×3000mm

CNC Press Brakes

Accurate bending with ±0.1mm repeatability

MAX LENGTH

3000mm

MODELS

RG-100, RG-60, RG-40

Material Processing Line

In-house material prep for faster production starts

EQUIPMENT

Leveler + 2 Shears

CAPABILITY

Coil-to-blank processing

CNC Machining Centers

In-house tooling for faster lead times and modifications

WORK ENVELOPE

1800 × 920mm

MODELS

TCGS-1625B, TCGS-1580

Wire EDM (Fast/Medium/Slow)

Precision die components with tight tolerances

BREAKDOWN

4 Fast + 5 Medium + 3 Slow

MAX SIZE

1000 × 800mm

Surface Grinders & Drills

Complete in-house tool finishing capability

GRINDERS

4 Units (KENT, Guibei)

DRILL PRESSES

7 Units

Integrated Finishing

525m Automated Powder Coating Line

Swiss Gema spray system with automated application and manual touch-up.Complete pre-treatment, coating, and curing in one continuous process, eliminating outsourcing delays and quality inconsistencies. Capable of coating parts up to 2200×1500×600mm.

525 m

Line Length

15,000 m²

Daily Capacity

1,050

Hooks

Gema Spray System

Consistent film thickness and color matching

type

Auto + Manual Touch-up

LINE SPEED

3.0 - 6.0 m/min

Pre-Treatment System

Proper surface prep for lasting adhesion

PROCESS

Multi-stage cleaning

Type

Iron Phosphate

Final Assembly Lines

Ship complete, ready-to-install products

LINES

6 Production Lines

CAPABILITY

Full product assembly

Coordinate Measuring Machine

Full 3D dimensional verification with reports

PRECISION

±0.003mm

OUTPUT

PPAP, ISIR, COC Reports

Optical Comparator

Fast 2D inspection for production parts

MODEL

VIEWMAX 3.22

APPLICATION

2D Inspection

Salt Spray Test Chamber

Verify corrosion resistance before shipment

STANDARD

ASTM B117

CAPABILITY

500+ hour testing

Tensile Testing Machine

Verify material properties and strength

TEST TYPE

Tensile / Compression

OUTPUT

Digital test reports

Coating Quality Instruments

Ensure finish meets customer specifications

INSTRUMENTS

Color, Gloss, Thickness

MODELS

CR-400, TC-880, WGG60-Y4

Cupping Test Machine

Verify material formability for deep drawing

TEST

Erichsen Cupping

Model

QBT-11

Visit Our Facility

We welcome customers, partners, and prospects to visit our manufacturing facility. See our operations firsthand and meet our team.

ZAK Manufacturing Facility

Strategic Location in China’s Manufacturing Hub

Address:

Nanhai Economic Development Zone

Foshan, Guangdong Province

China, 528225

Guangzhou Port

45 km

Guangzhou Baiyun Airport

55 km

FoshanXi Railway Station

15 km

Shenzhen / Hong Kong

~2 hours

Inside Our Facility

A glimpse into our daily operations and manufacturing environment

Ready to See More?

Whether you’re ready to start a project or just exploring options, we’d love to show you what ZAK can do.