Custom Sheet Metal Welding Services

Get precision joining for your sheet metal assemblies, from single prototypes to 100,000+ monthly units, our IATF 16949 certified welding integrated with your fabrication for complete, ready-to-use components.

What is Sheet Metal Welding

Welding permanently joins metal components through controlled heat and pressure, creating bonds as strong as the base material itself. As a critical step in our sheet metal fabrication process, welding transforms your laser-cut and CNC-bent parts into complete, production-ready assemblies.

Common Welding Applications in Sheet Metal Fabrication

- Structural Joining

- Enclosure & Housing Assembly

- Component Attachment

- Sub-Assembly Creation

- Cosmetic & Visible Joints

- Functional Requirements

The Right Weld for Every Application

Not every joint needs the same approach. We match the optimal welding method to your part’s requirements—balancing strength, appearance, speed, and cost.

When you need thousands of consistent joints per day without consumables eating into your margins, spot welding delivers. Each weld takes under a second, and our 18 stations mean your order won't wait in queue.

No filler material—eliminates wire/gas costs on high-volume runs

Sub-second cycle—keeps your unit cost low at scale

Minimal heat zone—no warping on thin panels

18 dedicated stations—capacity when you need it

HVAC condenser frames, automotive brackets, appliance housings, or any assembly requiring dozens of joints per part at production volumes.

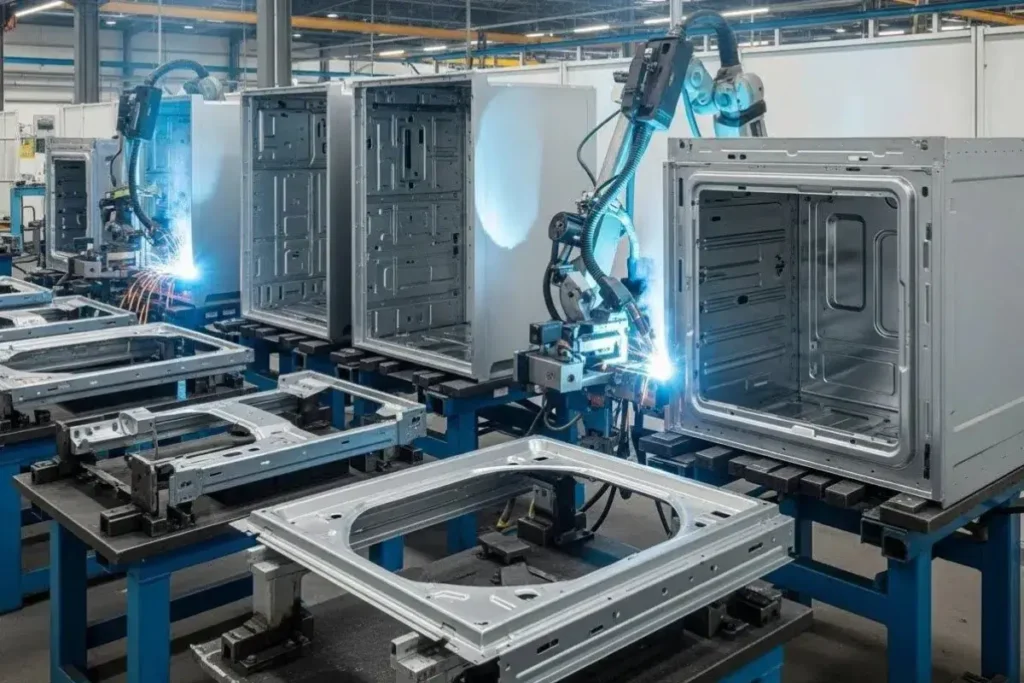

When your weld will be visible to end customers—or your geometry demands precision a human hand can't sustain across 10,000 parts—our FANUC robotic cells deliver ±0.1mm repeatability, batch after batch.

±0.1mm accuracy—cosmetic welds that don't need grinding

Minimal distortion—thin materials stay flat

Complex 3D paths—reaches angles manual welders can't

Batch consistency—part 10,000 matches part 1

Automotive sunroof frames, visible consumer product seams, intricate bracket geometries, or any application where inconsistency means rejects.

When your assembly needs to bear serious loads—equipment frames, structural supports, heavy-gauge enclosures—MIG welding deposits strong, deep-penetrating joints that won't fail under stress.

Deep penetration—structural joints that hold under load

High deposition rate—faster on thick materials

Versatile materials—carbon and stainless steel

Cost-effective—economical for larger weld beads

Equipment frames, machine guards, structural brackets, industrial enclosures, or any assembly where joint strength matters more than aesthetics.

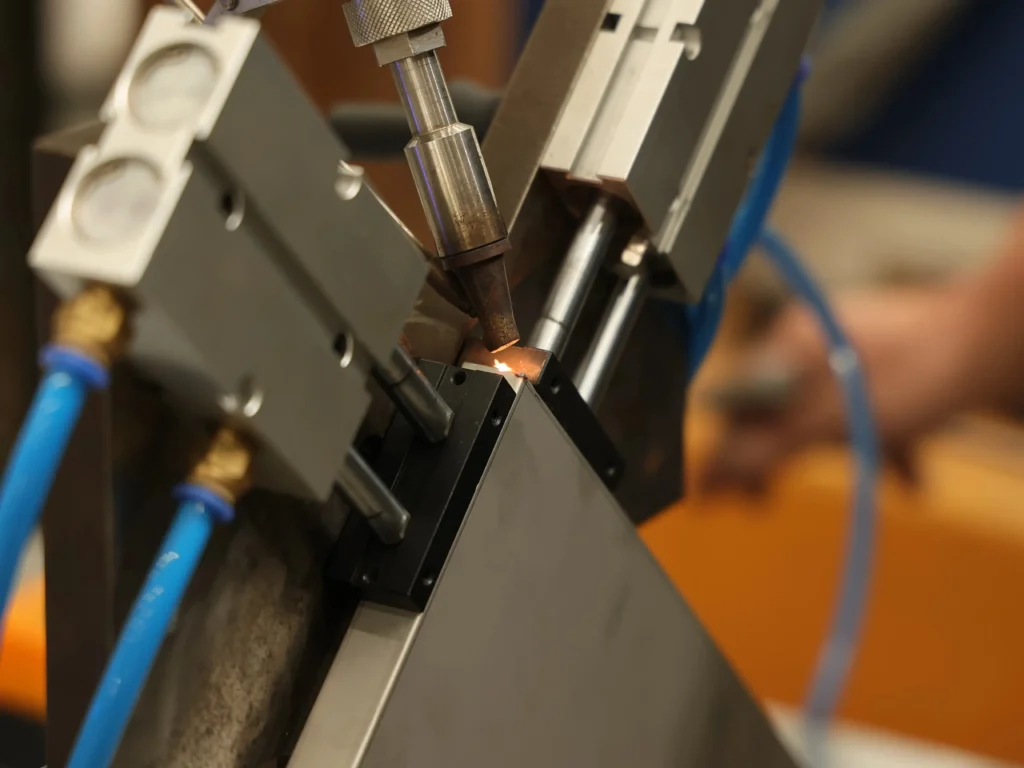

When the weld IS the product—architectural metalwork, premium appliances, visible stainless joints—our certified TIG welders create smooth, clean beads that require zero post-processing. Also your go-to for aluminum.

Show-quality finish—welds you're proud to display

No spatter—clean surrounding surfaces

Aluminum capable—your lightweight material option

Prototype friendly—perfect for development runs

Architectural metalwork, food equipment (sanitary welds), aluminum enclosures, prototype development, or any application where the weld must look as good as it performs.

What We Can Weld for You

From condenser frames to sunroof assemblies—see the range of welded components we deliver to OEMs and Tier 1 suppliers daily.

HVAC Components

- Condenser unit frames

- AC outdoor unit housings

- Fan motor mounts

- Compressor brackets

Automotive Parts

- Sunroof frame assemblies

- Seat bracket weldments

- A/B-pillar components

- Battery tray assemblies

Electrical Enclosures

- Cabinet corner joints

- Panel-to-frame attachment

- Hinge and bracket welds

- Door frame assemblies

Home Appliances

- Refrigerator components

- Washer drum supports

- Dryer housing assemblies

- Oven frame structures

Industrial Equipment

- Machine guards and covers

- Equipment frames

- Structural brackets

- Safety enclosures

Custom Assemblies

- Prototype weldments

- Multi-part sub-assemblies

- Mixed-material joins

- Special configurations

Quality That Meets Automotive Standards

Every weld is performed under the same quality management system that governs our IATF 16949 certified processes.

Certifications

- IATF 16949:2016

- ISO 9001:2015

- ISO 14001:2015

Weld Inspection

- Visual inspection

- Dimensional verification (CMM)

- Pull/push tests for spot welds

Testing Capabilities

- Destructive testing (cross-section)

- Salt spray testing

- Dimensional verification (CMM)

Why Choose ZAK for Welding

The Integrated Manufacturing Advantage

Shipping parts between multiple suppliers

Single-source: Cut → Bend → Weld → Coat → Ship

Communication gaps & coordination overhead

One project manager, one quality system

Quality inconsistencies across vendors

IATF 16949 certification across all processes

Extended lead times from multiple handoffs

Integrated workflow reduces handling time

Finger-pointing when defects occur

End-to-end accountability from one partner

Integrated Manufacturing

Welding connected to laser cutting, CNC bending, powder coating, all under one roof

Automotive Grade Quality

IATF 16949 procedures apply to every welding operation

Automation Investment

FANUC robots ensure repeatability and consistency at scale

40 Years Experience

Welding expertise refined since 1985, with experienced engineers and workers

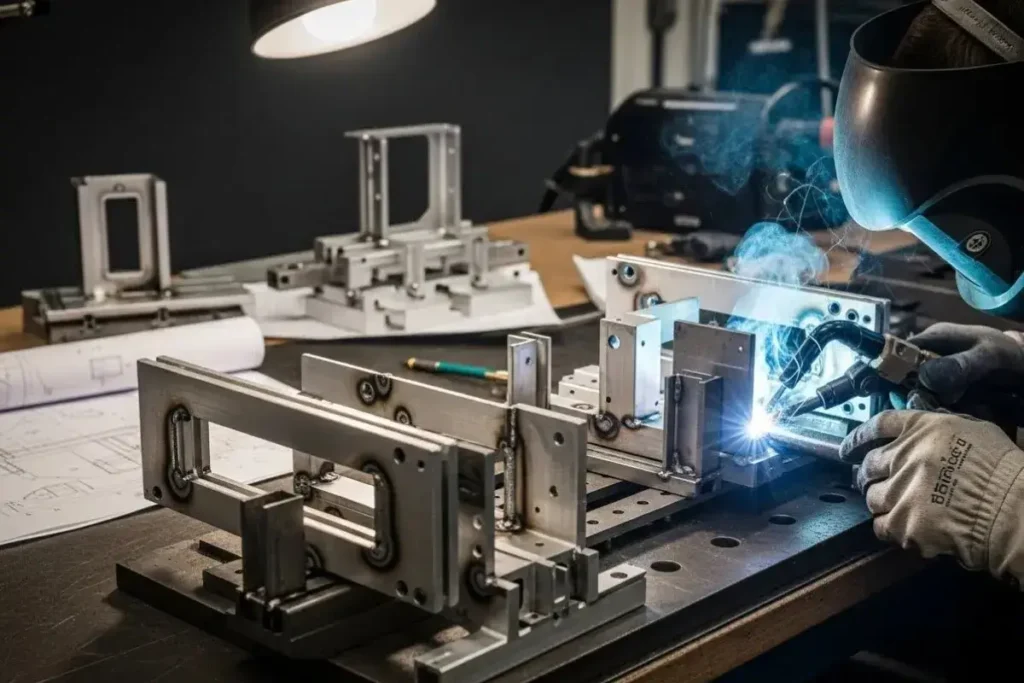

How Your Welded Assembly Is Made

Review

Cut

Bend

Finish

Ship

Our Welding Process

Fixture Setup

Custom jigs ensure repeatability

Weld Sequence

Optimized to minimize distortion

In-Process Check

First-off approval per shift

Post-Weld

Spatter removal, cleaning

Inspection

Per drawing callouts

Recent Welding Projects

Real projects. Real welds. See the quality and precision our team delivers daily.

Welding Capability Overview

Quick-reference specifications for engineers and procurement teams.

| Parameter | Capability |

|---|---|

| Spot Welding Stations | 18 units |

| Robot Weld Cells | 2× FANUC |

| Laser Welders | 2× Honglei |

| Material Thickness | 0.2mm – 6.0mm |

| Max Assembly Size | 2000mm × 1200mm |

| Material Types | Carbon, stainless, galvanized, aluminum |

| Monthly Capacity | 500,000+ spot welds |

| Quality System | IATF 16949, ISO 9001 |

Need specs outside these ranges?

Frequently Asked Questions

What types of welding does ZAKFAB offer?

We offer spot welding (resistance), robotic laser welding, MIG welding, and TIG welding. Our primary capability is high-volume spot welding with 18 dedicated stations, complemented by FANUC robotic laser welding for precision applications.

What's the minimum order quantity for welded assemblies?

We support everything from prototype quantities (1-10 pieces) to production volumes (100,000+ per month). Our flexible capacity allows us to scale with your project needs.

Can you weld my laser-cut parts from another supplier?

While we can accommodate this, the best results come from our integrated process where we control cutting, bending, and welding tolerances together. This eliminates fit-up issues and ensures consistent quality.

Do you provide weld samples before production?

Yes, we provide first-article samples with full dimensional reports. If specified, we can also include destructive test results showing weld cross-sections and pull-test data.

What certifications cover your welding process?

Our welding operations are covered under IATF 16949:2016 and ISO 9001:2015 quality management systems. All welders are certified per applicable standards.

Can you weld aluminum?

Yes, we have TIG welding capability for aluminum up to 2mm thickness. For aluminum applications, we recommend discussing your specific requirements with our engineering team.

Have a question not answered here?

Complete Your Assembly

Welding is one step in our integrated fabrication process. Explore the capabilities before and after welding.

Before Welding

After Welding

Ready to Get Started?

Whether you have detailed CAD files or just a napkin sketch, we’re ready to help bring your project to life. Start with a quote request, or schedule a call to discuss your requirements.